Progea Leonardo, in partnership with K.L.A.I.N. Robotics, launches a new lipstick packaging system. This can be possible using the anthropomorphic robot “DENSO” mod. VS6577 that it ensures a 70 pieces/min flow, increasing the productivity of their work by 110%.

In Progea Leonardo, a young and innovative reality that has been working for years in the field of special machines and mechanical equipment (in particular they follow the entire design phase, up to the realization of the machinery itself) they like challenges. Above all, they love overcoming them. Exactly how it recently happened with the new lipstick packaging system, created in partnership with K.L.A.I.N. Robotics. The system, design for a renowned Italian cosmetic company, can reach 70 pieces/per minute and it was design to provide high standards and maximum precision.

Among all the fields where it operates, the cosmetic one is very fascinating and it’s the reason that, in the last four years, Progea Leonardo started to produce machines to compact make-up powder, or to handle finished products such as lipsticks and mascaras, and volumetric dosing for creams and liquids. Research, design and automation are the key components that support Progea Leonardo and its growth and that led to the meeting with K.L.A.I.N. Robotics, a company that distributes robots for the factory automation and mechatronics components for over 20 years. “During our technological scouting we had the chance to meet all the innovatives solutions that K.L.A.I.N. Robotics had to offer, with its highly specialized team – Angelo Giarola said, the Technical Engineer in Progea Leonardo. What we appreciate the most in this collaboration with K.L.A.I.N. Robotics is to have found a company, that just like us, is moved by great passion and positive energy”. Thanks to the use of the Robot Denso VS6577, it is possible to increase the productivity by 110%, in fact from an initial request of 60 pieces/min, the machine is now able to guarantee 70 pieces/min.

LIPSTICK PACKAGING

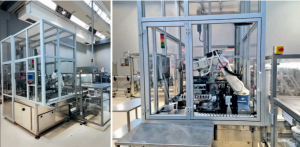

For packaging operations, they use the A19020 machine, designed to replace the operator upstream of the lipstick packaging line. Designed and built in a single load-bearing structure, the machine is divided into 3 distinct areas, load ‘A’, pick and place ‘B’, empty thermoformed unload ‘C’; all these areas are controlled independently by a PLC Safety.

The first area ‘A’ is dedicated to the loading area of the lipsticks trays where an operator places inside a trolley made of 13 shelves two thermoformed plates containing 110 lipsticks each. Obviously in order to guarantee a continuous efficiency to the machine and to avoid waste of time, more carts were built to allow operators to fill these ‘buffers’ while the machine is working. The second area ‘B’ is the work place with: an anthropomorphic robot Denso VS6577 with a controlled vacuum tool with two independent sockets, a mechanical rotating table with 4 position which is used to place the robot in the area from the buffer to the empty thermoformed unload position. In the same ‘B’ area, there is a small independent pneumatic station that is referred as ‘the accordion’ because of its movement and also, a precision chain belt with porters dedicated to the storage of the product upstream of the packaging and labeling line. In the end, we have the unload area ‘C’, where a small warehouse and a pneumatic 4 axis pick & place are positioned, that it has the task of picking up from the rotating table the empty thermoformed and put it in the empty discharge area. Tops, it can reach the amount kept in 4 trays. Why was it chosen to divide the machine in 3 different areas? Because in this way, the production of the line is not penalized, and it’s always ensured at least one pick up and one delivery from the anthropomorphic robot without the need to re-equip the auxiliaries every time the doors for extraction and insertion open or for the manual emptying of thermoformed. This was the winning move that allowed to fulfill the client’s requests, increasing the production times by 10% more than what they were used to with manual operations.

HOW IT WORKS

The following is a brief description of how the machine works, beginning from its ignition. The activation from an operator is possible by turning the 400 Vac general switch on, placed on the electrical panel. Electrically started, the auxiliaries that operate the 24 Vdc circuits are activated by the control panel that – in turn – also put into action the 6 bar compressed air utilities in the various pneumatic cylinders. At this point you must zero the electrical axes of the machine, vertical loading axis of the trolley area ‘A’, horizontal loading axis of full thermoformed trays from the trolley on the table area ‘B’ and you need to make sure that the robot is in its home position.

Once the wipes are completed, we can prepare the machine load. The loading warehouse door is opened, you insert the tray with all the 26 thermoformed lipsticks, you block it with the lock bracket controlled by a sensor, you close the warehouse door and you push the light blue button to activate the auxiliaries of area ‘A’. Now, you go in front of the touch screen panel, you automatically place the ‘key’ on the mini pendant (of the robot Denso), and start the “start cycle” on the home page. The tray with the thermoformed begins to go vertically up ‘area A’ to position itself on the first tray. This operation will be repeated for 13 times. After that, the tray will be totally empty and ready to be replaced by another one full. When the tray is in the correct position, the loading axis extends itself up to stand directly under the first tray, a small pick & place lifts it from the cart, letting the axis-arm to return in a folded position under the table, delivering the tray full of ‘buffer’ of the rotating table. Once received the electronic consent of correct delivery, the board can rotate to place the thermoformed in the Robot delivery area. Once the correct presence of the tray is noted, the robot starts to pick the 11 lipsticks one at the time with the tool and to place them on the accordion station that takes care of enlarging the wheelbase among the lipsticks. Copying exactly the porters’ steps on the deliver conveyor belt. It’s in this phase that the Denso Robot picks them up with the vacuum tool, but in the second position they have the same space to the one in the pneumatic accordion station, and it ships the lipsticks on the conveyor belt with porters. Obviously, the delivery on the belt happens only if the downstream conveyor belt with porters is functioning and the PLC has confirmed the possible delivery in the cited area and controlled by photocells.

The application is highly performing, and it can handle up to three different types of lipsticks, with a simple quota change. About the management and the use of the new machine, Angelo Giarola said:” We plan to invest in the present and to use robots for various customized applications”. It is clear that the company, with a vision towards the satisfaction of all the market needs, aims to a constant growth, and it looks forward to becoming a strategic partner for development and innovation.

The application is highly performing, and it can handle up to three different types of lipsticks, with a simple quota change. About the management and the use of the new machine, Angelo Giarola said:” We plan to invest in the present and to use robots for various customized applications”. It is clear that the company, with a vision towards the satisfaction of all the market needs, aims to a constant growth, and it looks forward to becoming a strategic partner for development and innovation.

“RMO”, Maggio 2020