Company: AIRBUS

Industry: Aerospace

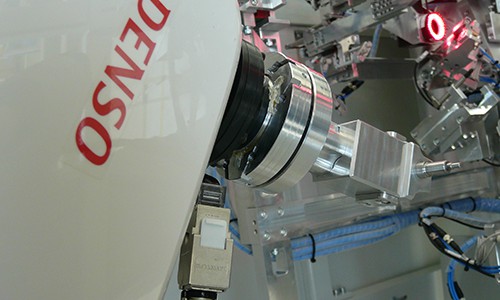

DENSO Products Used: VM-60B1G-V

Company Location: Germany

Website: http://www.airbus.com

THE PROBLEM

Airbus studies and tests the flow behaviour and the flight capability of diverse airplane types- especially wings and engines- that are essential components for the development and manufacturing of new aircraft types. The Airbus Low Speed Wind Tunnel (LSWT Bremen) has been designed to analyse the performance of aircrafts during take-off and landing. It also studies factors such as pressure, stress and temperature at speeds of up to 85 m/s. Multi-hole pressure probes play a decisive role in this process because they are efficient and reliable tools to precisely measure flow conditions. As expected, all probes used for this purpose have to be calibrated accurately.

THE SOLUTION

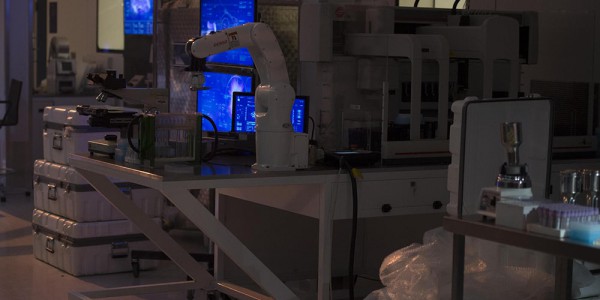

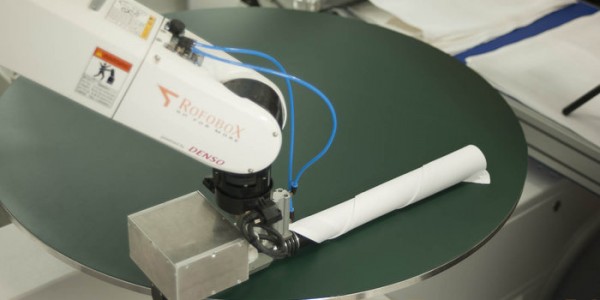

Probes are checked with the support of a DENSO VM-60B1G-V robot either before or after every test or during a flight simulation.

“Contrary to most robotic applications, in this case, the most important is not speed but absolute accuracy”, explains Airbus’ project manager. “In this way, it is easy to decide whether or not a new calibration is necessary or whether additional tests can be performed.” In order to decide this, the probes are exposed to a flow field with known speed and direction. The robots carry out the movements of the probes within the measuring grid and the results obtained are then compared with the calibration values.

“The simplicity to operate the robots and the free choice to communicate with them using our own software is a great advantage.” says the responsible engineer at Aerodynamics Testing at Airbus. “Additionally, with its six axes, the robot is extremely flexible when operating in a three-dimensional grid with 1,000 measuring points. You have the opportunity to control the robot in such way that it is possible to check the same measuring point for one minute.” Previously, inflexible rotating discs inconveniently carried out these tasks.

THE RESULT

Thanks to the flexible robot programming language, data transfer into the evaluation program of the laboratory is possible. “I have never seen such flexibility in robots“, emphasizes the project leader – this department in particular uses highly individualized and self-developed software tools and programming language.

The Robot has six arms and is extremely flexible. This makes it easy to work in a 3D grid with 1,000 metering points for example. Furthermore, it is possible to access the device directly, which enables analyzing the metering points in more detail.

DENSO robots have been employed at Airbus since 2008.